🚚 📦 Takeaways from MODEX 2024

Supply chain robotics take center stage

Image credits: MODEX2024 Website

MODEX 2024 did not disappoint! The convention center was packed with supply chain experts representing companies throughout the value chain. This year’s exhibitions were different from prior years because autonomous robots were front and center. Most exhibitors had some form of autonomous system actively operating while on display, whether they were an OEM, or end user (Locus robotics’s bots were unsurprisingly everywhere). Being at this show was a glimpse into the future of supply chain automation. More than anything, the takeaway is that automation of warehouse operations is truly top of mind for robot purchasers in the industry, and companies of every size are putting serious financial backing behind the goal.

This revelation came as a nice counter insight to the declining sales of industrial robots in 2023... in fact, it even supports it. Few companies at MODEX were showing off traditional, single point robotics automation solutions. Instead AMRs, smart robots, and other autonomy-first solutions were the darlings of the show. I was intrigued by the autonomous truck loading and unloading solutions in particular. These demonstrated the new way of building in robotics and many of them fit my definition of a “Productive Robot” or “Probot” - more insight on that here and a full report in the works.

My favorite trailer unloading Probots at MODEX

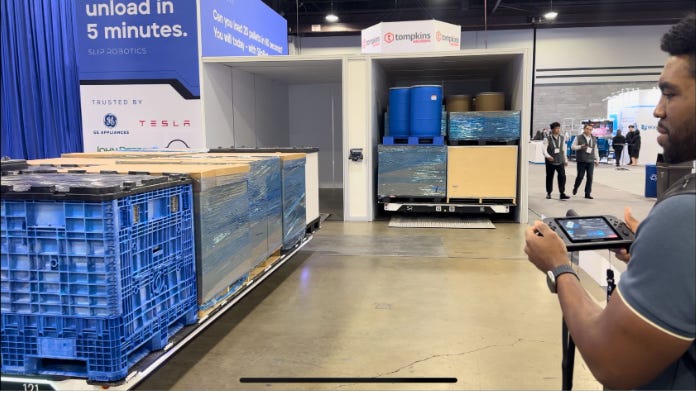

1. Slip Robotics

Slip robotics showcased trailer loading and unloading of palletized goods using their robotic truck bed. I tested out the robot and the experience was frictionless. I controlled the robot with a modified Nintendo Switch controller (and it was much easier to operate than any video game I’ve ever played). Familiar controls made it extremely simple to pan, or rotate (perfectly in place). When the robot was able to squarely identify the opening of the trailer, I had the option to enter an auto-homing mode, at which point the robot would autonomously make final adjustments and enter the trailer. Brilliant engineering - winning the show's “Best New Innovation” award.

2. Anyware Robotics

Anyware Robotics was another favorite of mine. They differentiated themselves from others in two ways. First, they are using nearly 100% off the shelf hardware, pushing the complexity to the software level. This enables them to rapidly iterate through the physical development of the entire system and opportunistically choose the most functional subsystems for their tech stack. When deployed in a warehouse, their bot can identify the trailer and get right to work without excessive oversight. Their second advantage is their proprietary conveyor system. With the mobile conveyor, the robot head does not need to travel to end of the trailer with every pick cycle. Instead, it simply pulls the boxes out onto the conveyor immediately in front of the boxes starting position. The addition of the conveyor more than halves the cycle time, and even more critically, boosts reliability since the robot does not have to carry boxes dynamically through free space (although of course it still can).

3. Pickle Robot Co

Pickle has been a player in the space for some time and it was impressive to see how far they have come even in the last 12 months. Their system was reliably unloading the truck throughout the demo, and they featured a live analytics dashboard to monitor system performance. They also are intentional about capturing the robotics controls data from every pick, enabling them to continuously improve their AI model.

4. Contoro Robotics

Contoro Robotics is a newer player in the space and is making rapid progress by leveraging teleoperations to improve reliability. The robot can of course autonomously pick up cases, recognize text, and palletize them, but for fast initial training and additional fault tolerance the operator can take control of the system remotely. Contoro is a great example of a lightweight and cost effective hardware build that is focused on solving the customer needs rather than building complex tech for the sake of it.

5. Boston Dynamics - Stretch

Boston Dynamics’s Stretch robot was almost cathartic to behold. It appeared to be the smoothest and most powerful of the non-palletized unloading solutions (witnessing BD’s engineering prowess is always inspiring). As an added bonus, Stretch routinely (and easily) unloaded 50lb+ boxes as part of the live demo, (which others were not showing). The consequence was that some of the heavy boxes were misplaced and fell off of the side of the conveyor before exiting the truck. Ultimately, at the of the demo a hired human operator had to go into the trailer to rescue the lost packages. Undoubtedly, they will use this data to improve robustness as time progresses!